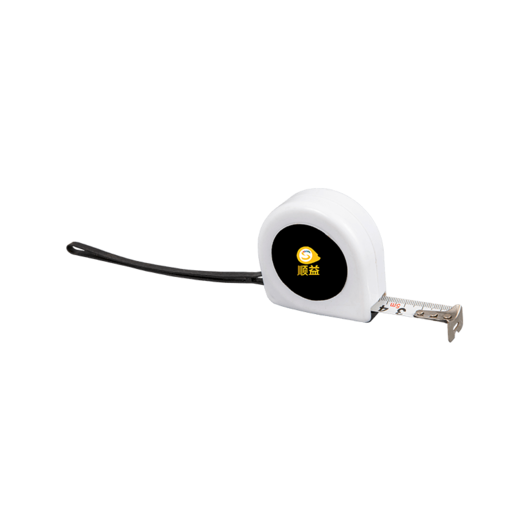

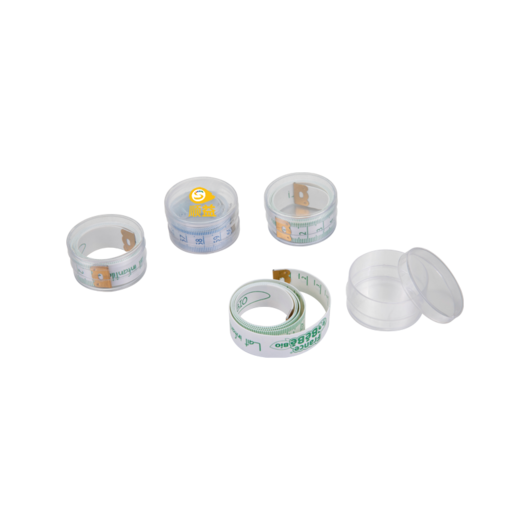

Surface quality of tapes and boxes

1. The surface of the nickel-plated and chromium-plated tape should be free from defects such as peeling and rust;

2. The galvanized tape should undergo a 24h neutral salt spray test, and its corrosion protection rating should not be lower than level 3;

3. The surface of the coated tape should be smooth and firm with uniform color;

4. The thickness of the bidirectional coating on the surface of the tape should not be less than 15μm;

5. The coating adhesion of the coating tape should not be lower than grade 3 after measurement;

6. The coating flexibility of the coating tape measure should be free of reticulate, crack-level peeling and other phenomena after testing;

7. The coating of the coated tape should be subjected to an uninterrupted sand washing test of 8kg20# emery. After the test, there is no erosion or peeling of the marking lines and character marks on the ruler surface.

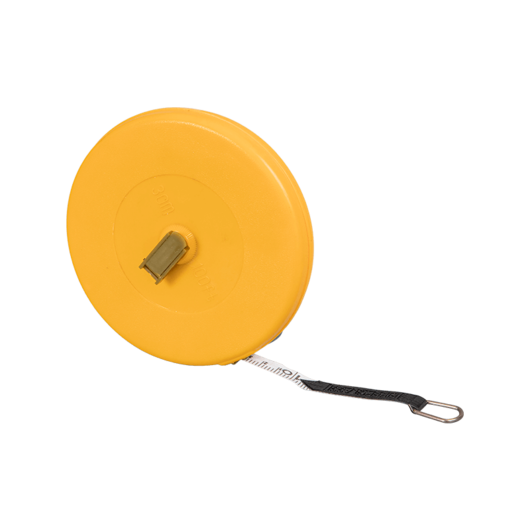

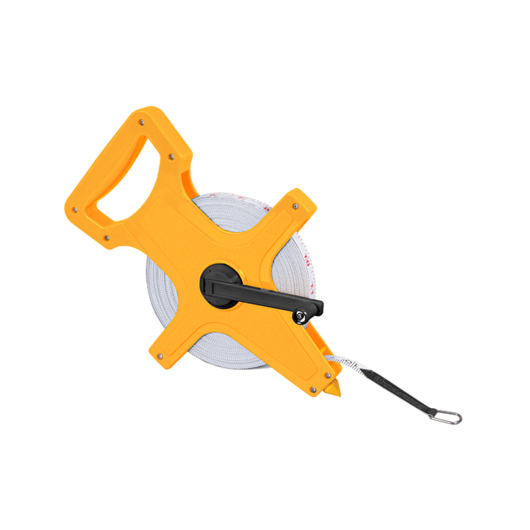

Ruler box surface quality:

1. The characters and marks on the surface of the metal ruler box should be clear and complete;

2. The covering layer of the ruler should be uniform in color, smooth in surface and no rust;

3. The electroplated metal ruler box should undergo a 24h neutral salt spray test, and its corrosion protection rating should not be lower than grade 5;

4. The surface of the plastic ruler box should be uniform in color, smooth and complete;

5. When the edge of the ruler box is marked with dimensions, the shape and attachments of the ruler box shall not interfere with the measurement.

English

English Español

Español