Hot Products

-

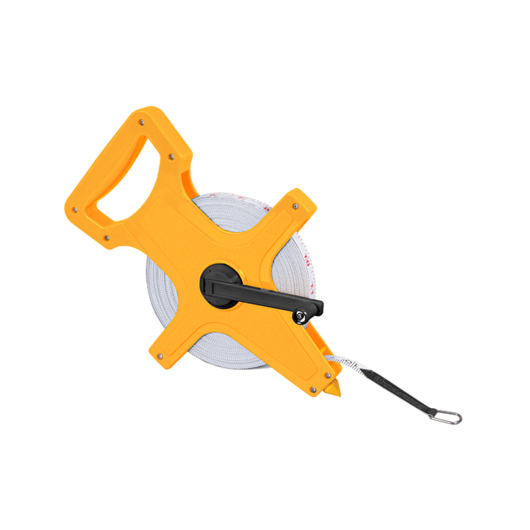

Custom Printing Tape Measure CRP-09

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

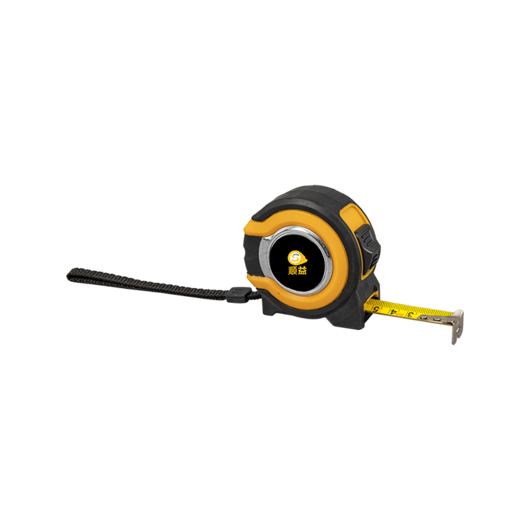

Custom Measuring Fiberglass Tape Measure CRP-12

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

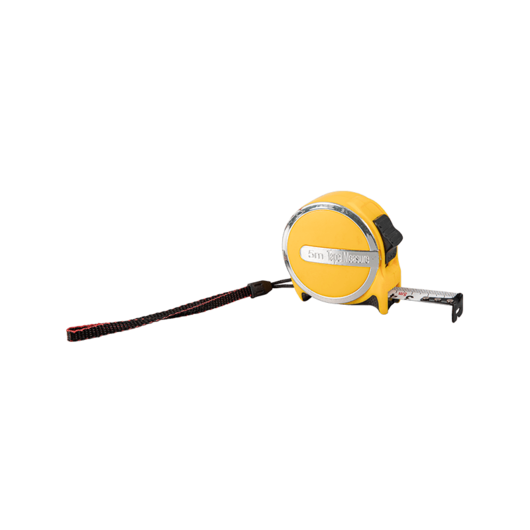

Abs Portable Fiberglass Tape Measure CRP-J1

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

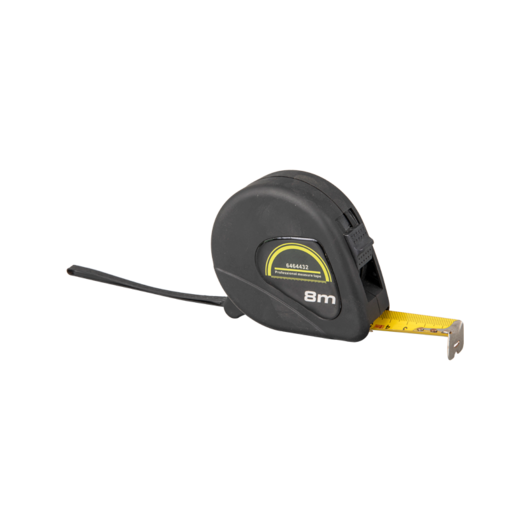

Printing Legible Abs Plastic Shell Tape Measure CRP-J3

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

Retractable Fiberglass Tape Measure CRP-J8

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

Magnetic Tip Steel Tape Measure Cr-j4

Main Features Feet with a high grade of glass fiber.printing legible and resistant to wear.Foot high-strength ABS plastic shell.

See Detail -

Stainless Steel Tape Measure Cr-j5

Main Features Feet with a high grade of glass fiber.printing legible and resistant to wear.Foot high-strength ABS plastic shell.

See Detail -

Tape Measure SY-T02

Main Features 1.Magnetic tip easy measurement by one person. 2. Stainless steel protector. 3. Ergonomically designed case with nylon coated blade.

See Detail -

Retractable Tape Measure SY-T04

Main Features 1.Magnetic tip easy measurement by one person. 2. Stainless steel protector. 3. Ergonomically designed case with nylon coated blade.

See Detail -

Nylon Coated Blade Steel Tape Measure SY-T14

Main Features 1.Magnetic tip easy measurement by one person. 2. Stainless steel protector. 3. Ergonomically designed case with nylon coated blade.

See Detail -

Retractable Tape Measure CRP-J7

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail

English

English Español

Español