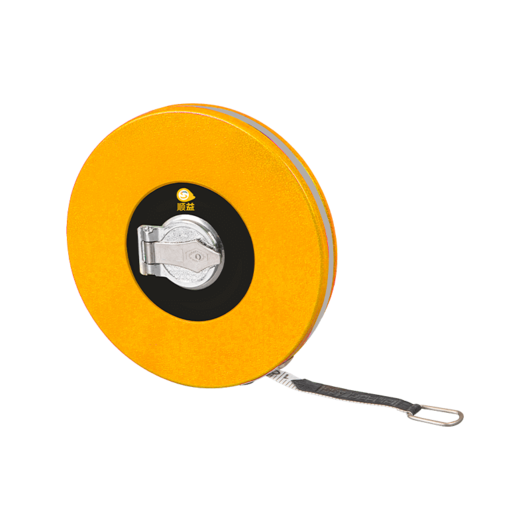

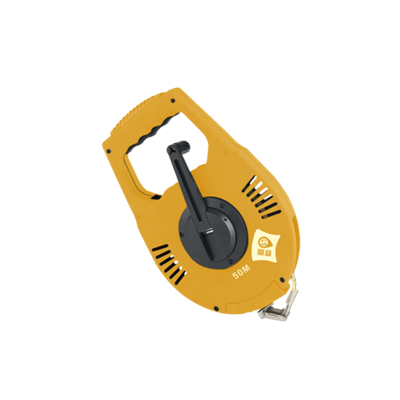

How to use steel tape measure

(1) Direct reading method

When measuring, the zero scale of the steel tape is aligned with the starting point of the measurement, and an appropriate pulling force is applied (the pulling force is subject to the appraisal pulling force of the steel tape or the calibrated pulling force on the ruler, measured with a spring balance), and directly reading the scale on the ruler corresponding to the end point .

(2) Indirect reading method

In some parts where the steel tape measure cannot be used directly, you can use a steel ruler or a square ruler to align the zero scale with the measuring point, and the ruler body is consistent with the measurement direction; use a steel tape to measure to a certain scale on the steel rule or square The distance and excess length are measured by the reading method.

(3) Several errors in steel tape measurement

The more accurate steel tape must be verified when it leaves the factory and after a period of use, and the temperature, tension and ruler length at the time of verification must be indicated. The length marked on the ruler is the nominal length, and the difference between it and the actual length is called the ruler length correction Δl. The ruler length will change when the ruler is subjected to different pulling forces. In order to avoid this change, it is required to use the steel tape in accordance with the tensile force marked on the ruler. The length of the steel tape will change at different temperatures, so a function with the temperature t as a variable must be used to express the length of the ruler. This is the ruler length equation, and its general form is:

lt=l+Δl+α·l(t-t0)

Where lt the actual length of the steel tape at temperature t;

l Nominal length of steel tape;

Δl length correction number, that is, the difference between the actual length and the nominal length of the steel tape at temperature t0;

α Thermal expansion coefficient of steel tape;

t0 The temperature when the steel tape is verified;

The temperature of the steel tape in use.

In the use of steel tape measure, the main causes of errors are as follows:

a. Error of temperature change

Generally, the thermal expansion coefficient of steel tape measure is α=1.25x10-5, which is only one-80,000th of the temperature difference per meter per degree, but the same steel tape measure will still produce a large length change under a large temperature difference environment. Measurement results. The error of temperature change has been considered in the ruler length equation.

b. Pulling force error

The size of the pulling force will affect the length of the steel ruler. If the spring scale is not used to measure the pulling force during measurement, errors will occur. The elastic modulus of steel E=2X106 KG/CM2. According to Hooke’s law, a 30-meter ruler will produce a length error of ±1.8 mm when the tension error is ±5 kg.

c. The error of the steel ruler not being level

When measuring the horizontal distance, the steel tape should be kept as level as possible, otherwise it will cause the error of distance increase. For a ruler length of 30 meters, when the height difference between the two ends of the ruler reaches 0.4 meters, an error of about 2.6 mm will occur, and the relative error is 1/11200.

English

English Español

Español