Hot Products

-

Resistant To Wear Tape Measure CRP-02

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

Stainless Steel Tape Measure Cr-j5

Main Features Feet with a high grade of glass fiber.printing legible and resistant to wear.Foot high-strength ABS plastic shell.

See Detail -

Custom Logo Tape Measure SY-T01

Main Features 1.Magnetic tip easy measurement by one person. 2. Stainless steel protector. 3. Ergonomically designed case with nylon coated blade.

See Detail -

Logo Printed Tape Measure SY-T03

Main Features 1.Magnetic tip easy measurement by one person. 2. Stainless steel protector. 3. Ergonomically designed case with nylon coated blade.

See Detail -

Custom Tape Measure SY-T05

Main Features 1.Magnetic tip easy measurement by one person. 2. Stainless steel protector. 3. Ergonomically designed case with nylon coated blade.

See Detail -

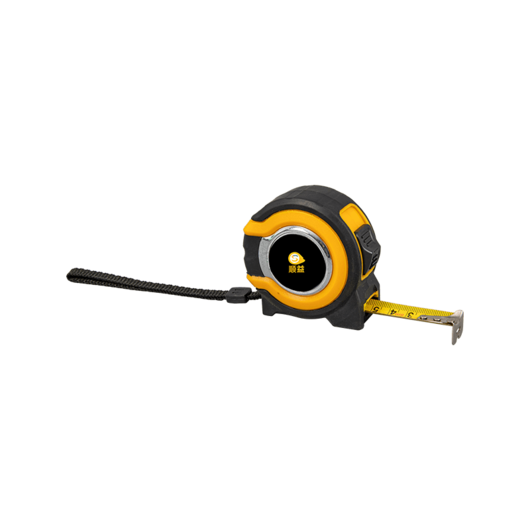

Magnetic Tip Easy Measurement Tape Measure SY-T07

Main Features 1.Magnetic tip easy measurement by one person. 2. Stainless steel protector. 3. Ergonomically designed case with nylon coated blade.

See Detail -

Mini Tape Measure With Keychain SY-M05-08

Product Name: Mini Tape Measure With Keychain SY-M05-08 Brand Name: SHUNYI Place of Origin: Zhejiang, China Model Number: SY-M05-08 Type: Business Gift Material: ABS Plastic+PVC(fiberglass) Lead Time: 30days Design: OEM/ODM Feature: Eco-friendly Packing: Color Box or according to customer requirement Sample: free of charge Customization: Customized logo Customized logo Graphic customization Any questions will be replied within 24 hours.

See Detail -

Flexible Colored Long Distance Tape Measure CRP-11

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

Portable Long Tape Measure CRP-J9

Main Features Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail -

Custom Resistant To Wear Tape Measure CR-J8

Feet with a high grade of glass fiber, printing legible and resistant to wear. Foot high-strength ABS plastic shell.

See Detail

English

English Español

Español